Let's talk about the ordinary gear reducer first. The ordinary gear reducer uses spur gears. The main disadvantage of spur gears is that vibration occurs during operation. This vibration cannot be eliminated, whether it is changing the design or manufacturing materials. Measures in this respect cannot be avoided. Some changes in the involute profile may occur along the entire tooth surface at the same time. This will lead to a regular and unsolvable problem, one contact of each tooth will occur.

Therefore, the generated vibration causes a large load on the gear, and also causes noise. Another disadvantage is that sometimes the additional strength obtained by the meshing of two pairs of teeth cannot be used during the contact time of the tooth and the tooth, because the stress is limited by the condition of the single tooth meshing in the cycle, so it will cause energy This problem is hoped to be improved in the future.

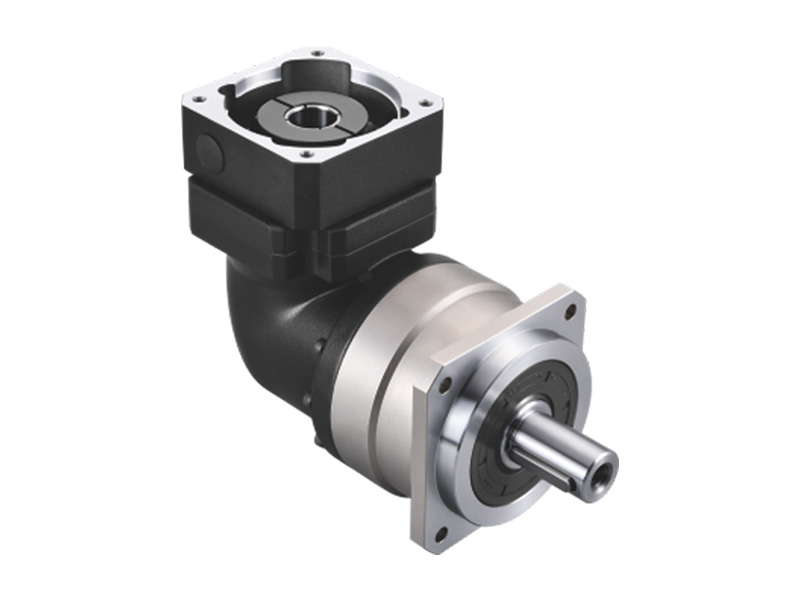

In turn, the helical gear planetary reducer is different. As the name implies, the helical gear reducer uses helical gears inside. The helical gears have higher transmission efficiency and perform better in transmission accuracy, especially in high-power planets. The reducer has higher torque and more stable transmission.

We can regard the helical gear planetary reducer as a set of cylindrical gears in which the flakes and gears are placed in a dislocation, so that when the gears are running, each piece of contact is on a different tooth gallery, so that the error of each flake gear can be effectively compensated. Compensation is very effective for the elasticity of the gear teeth. Therefore, the result is that all gears with an error within 10mm can average the error, thereby greatly reducing vibration, so under load, it can be combined with an error within 1mm The gear teeth run smoothly.

Because at any time, about half of the time (assuming the coincidence degree is about 1.5), there are two teeth biting each other, which brings additional benefits in terms of strength. Therefore, it can be based on 1.5 times the tooth width instead of a tooth width.

It is difficult and uneconomical to manufacture and assemble a large number of sheets to solve the problem of spur gears. Therefore, a helical gear reducer which is connected as a whole is invented, and the gears have gears along the direction of the spiral. Helical gears are not like spur gears in that they cause undesirable axial forces. But the advantages in terms of vibration and strength far outweigh the disadvantages caused by axial thrust and slightly increased manufacturing costs. Therefore, helical gears are used instead of spur gears in the manufacture of reducers.